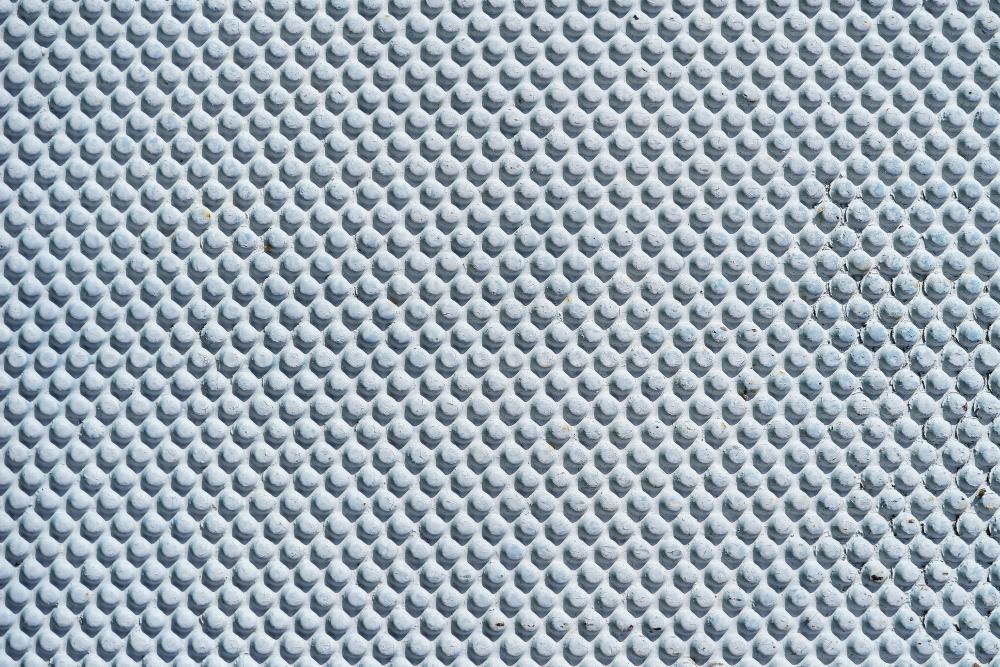

When it comes to combining strength, functionality, and aesthetics in metalwork, few materials rival the patterned steel options widely used across various industries. These textured metal panels offer more than just structural integrity—they deliver slip resistance, longevity, and a rugged visual appeal that suits both industrial and design-oriented Diamond Plate Sheets environments.

Why Textured Metal Panels Are in Demand

The unique surface of these materials features raised patterns that enhance grip, making them ideal for areas where safety is critical. Workplaces like factories, transportation vehicles, and loading docks rely heavily on them to reduce the risk of slips and falls. Homeowners, too, have discovered their usefulness in garages, workshops, and even home decor accents.

This demand stems from a material that not only resists corrosion and abrasion but also holds up under pressure in high-traffic or heavy-load scenarios. Commonly crafted from aluminum or steel, these panels are lightweight yet extremely durable, capable of withstanding harsh conditions without compromising performance.

Applications in Commercial and Residential Settings

Industrial Use

In industrial environments, these sheets are commonly used for flooring, stair treads, catwalks, and toolboxes. The non-slip surface is a safety feature that companies count on to protect their employees and improve efficiency. Moreover, they are easy to clean and maintain, reducing long-term maintenance costs.

Vehicle Fabrication

In the automotive and transport industries, these patterned panels are a standard feature in truck beds, trailers, and emergency vehicles. Their lightweight design doesn’t add much to the vehicle’s weight but still provides high resistance to wear and tear.

Residential Use

Homeowners are increasingly incorporating these metal sheets into their design plans. Whether it's for creating durable wall coverings, garage floors, or workbench surfaces, they blend practicality with a modern industrial aesthetic. Designers often use them to add a bold touch to interiors, such as kitchen islands, bar fronts, and cabinet panels.

Material Types and Finishes

There are several types of patterned metal sheets available, but the most common are made from aluminum or stainless steel. Aluminum versions are preferred for applications requiring lightweight material and corrosion resistance. Stainless steel offers a more robust solution, especially in areas prone to moisture or chemical exposure.

The finishes vary depending on the intended use—polished finishes for decorative projects or matte for utility-focused applications. These finishes also help resist scratching and maintain the panel’s appearance over time.

Customization and Fabrication

Modern metal shops can easily cut, shape, and weld these sheets to meet specific design requirements. Whether you're constructing a safety platform or a custom decorative piece, these materials adapt well to both standard and unique designs. Their versatility makes them a favorite for engineers, designers, and DIY enthusiasts alike.

Benefits of Using Patterned Metal Sheets

-

Slip Resistance: The raised pattern provides traction, making them ideal for safety-conscious installations.

-

Durability: They resist corrosion, weather, and wear, even in high-traffic or outdoor environments.

-

Low Maintenance: Easy to clean with basic tools and resistant to most stains or damage.

-

Visual Appeal: Industrial yet stylish, perfect for creating a modern look in both commercial and residential settings.

-

Easy to Install: These sheets can be installed using basic tools and techniques, making them accessible even for novice users.

Environmentally Friendly Choice

Many versions of these sheets are recyclable, making them a sustainable option for construction and renovation projects. Aluminum, in particular, can be recycled repeatedly without losing its structural integrity, supporting eco-conscious design initiatives.

Choosing the Right Type for Your Needs

Before purchasing, consider the environment in which the sheets will be used. For interior design or areas not exposed to harsh elements, aluminum versions are usually sufficient. For heavy-duty applications like manufacturing floors or external staircases, steel varieties are more suitable.

Also, think about size, thickness, and finish. Different thicknesses will affect strength and weight, and the right finish will protect the surface while matching your aesthetic vision.

Final Thoughts

While the name might not appear in the headline, these sheets play a critical role across multiple industries and households. Their functionality, safety features, and design flexibility make them one of the most practical solutions for flooring, structural supports, and decorative accents alike.

Whether you are an industrial engineer or a homeowner looking to add a rugged touch to your space, incorporating these versatile panels can lead to both performance and design benefits.