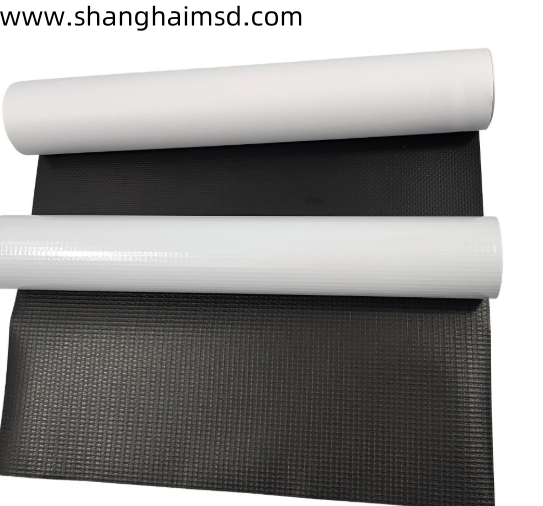

Inflatable Boat Fabric thickness plays a key role in how a vessel performs on water. The thickness level affects everything from structural support to air retention and surface durability. Selecting the appropriate material thickness is essential for achieving the balance between portability and protection.

A thicker inflatable boat fabric can offer greater resistance to abrasions and punctures, which is important for boats exposed to sand, rocks, or frequent docking. However, thickness also influences how the material handles—heavier fabrics may reduce flexibility and increase transport weight. Manufacturers must consider how a specific thickness will behave once welded, inflated, or stored.

At shanghaimsd, we supply inflatable boat fabric in a range of thicknesses to match different production demands. Our fabric coatings are designed to work seamlessly with either heat welding or adhesive bonding methods, helping create air-tight seals without compromising movement. Whether the requirement is for lightweight folding kayaks or reinforced multi-chamber rafts, we ensure consistency in thickness across each batch.

The relationship between fabric thickness and performance is also tied to user safety and comfort. Thinner fabrics may offer easy folding and packing, while thicker ones provide greater shape stability in water. Choosing the correct type depends on usage conditions and desired functionality.

For inflatable boat makers seeking reliable fabric solutions, shanghaimsd delivers materials that meet a range of structural and practical needs. Explore our inflatable fabric collection and product specs by visiting: https://www.shanghaimsd.com/