-

Fil d’actualités

- EXPLORER

-

Pages

-

Groupes

-

Blogs

-

Développeurs

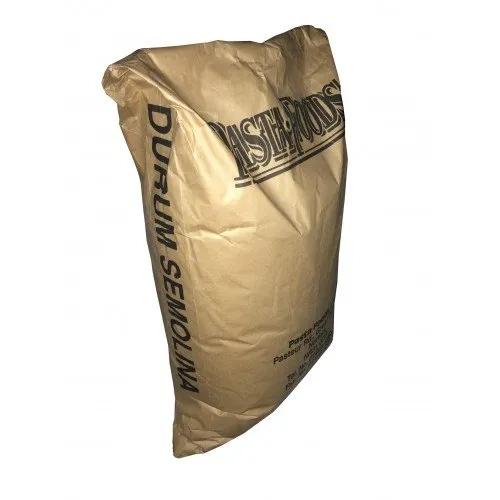

Chemical Paper Bags – Safe & Sustainable Packaging for Industries

When it comes to packaging sensitive products like chemicals, fertilizers, and powdered materials, safety and durability are non-negotiable. That’s where Chemical Paper Bags come into the picture. Designed to combine strength with sustainability, these bags have become an industry standard for businesses looking for reliable and eco-conscious packaging.

What Makes Chemical Paper Bags Special?

Unlike regular paper bags, chemical paper bags are manufactured using high-grade kraft paper and often include inner linings of polyethylene or other protective materials. This multi-layer structure provides the durability needed for industrial products while keeping contents safe from moisture, leakage, or contamination.

They are engineered not just to hold weight, but also to maintain the integrity of the chemicals inside, ensuring they remain effective from production to end use.

Key Benefits of Chemical Paper Bags

-

Strength and Durability – Multi-ply construction ensures that bags do not tear easily, even with heavy loads.

-

Moisture Resistance – Protective coatings or liners safeguard chemicals from humidity and dampness.

-

Eco-Friendly – Made from recyclable and biodegradable kraft paper, they support sustainable packaging initiatives.

-

Safe Handling – Designed to prevent leaks, spills, or dust, making storage and transportation safer.

-

Customizable – Can be printed with branding, product details, and safety instructions.

Common Applications

-

Fertilizers and Pesticides

-

Powdered Chemicals like lime, carbon black, or silica

-

Food Additives & Ingredients (when using food-grade paper)

-

Construction Materials such as cement or gypsum

-

Pharmaceutical Raw Materials

These applications highlight the versatility of chemical paper bags across multiple industries.

Why Industries Are Switching to Paper-Based Solutions

With stricter regulations around plastic use and increasing awareness about environmental sustainability, industries are seeking alternatives that are safe, cost-effective, and environmentally responsible. Chemical paper bags check all these boxes by offering:

-

Better branding opportunities with high-quality printing.

-

Compliance with eco-friendly packaging standards.

-

A balance between strength, safety, and sustainability.

Conclusion

The packaging industry is evolving, and chemical paper bags are at the forefront of this transformation. Their ability to protect industrial chemicals while minimizing environmental impact makes them a smart choice for businesses worldwide. Strong, safe, customizable, and eco-friendly these bags are more than just packaging; they are a commitment to quality and sustainability.

- Books

- Software

- Courses

- Film

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness