3D Printing Gases Market Challenges: Growth, Share, Value, Size, and Scope By 2034

Executive Summary: 3D Printing Gases Market Size and Share by Application & Industry

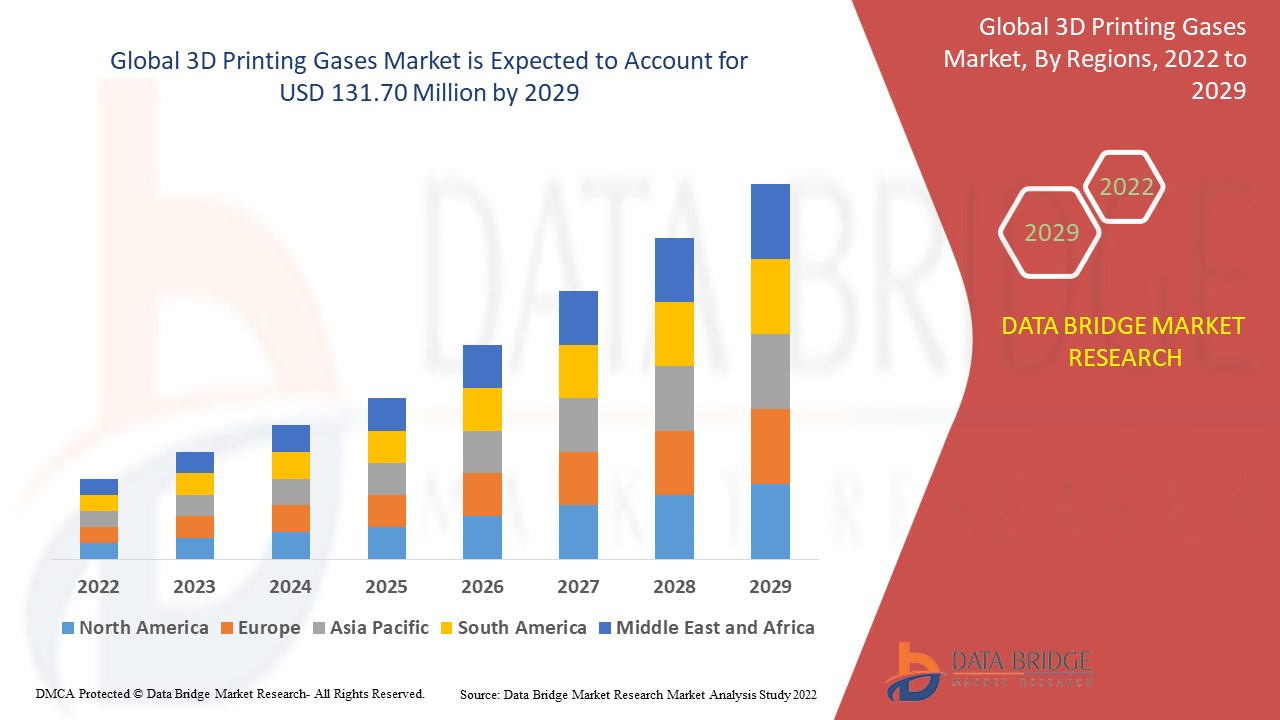

Global 3D printing gases market size was valued at USD 72.63 million in 2024 and is projected to reach USD 188.21 million by 2032, with a CAGR of 12.64% during the forecast period of 2025 to 2032.

A worldwide 3D Printing Gases Market report comprises of the most recent market information with which companies can have thorough analysis of 3D Printing Gases Market industry and future trends. By applying market intelligence for this report, industry experts assess strategic options, outline successful action plans and support companies with critical bottom-line decisions. Competitive analysis studies of this market report aids to get ideas about the strategies of key players in the market. Not to mention, the scope of 3D Printing Gases Market business report can be broadened from market scenarios to comparative pricing between major players, cost and profit of the specified market regions.

3D Printing Gases Market research report analyses key factors of the market which offers precise data and information for the business growth. This market analysis report makes an assessment of the expected rise, growth or fall of the product in the specific forecast period. For acquiring detailed market report, request an analyst call or drop down an enquiry at any time. The data gathered to prepare this report is based on the data collection modules with large sample sizes. The persuasive 3D Printing Gases Market report includes all the company profiles of the major players and brands.

Discover how the 3D Printing Gases Market is changing with key trends and forecasts. Access the report:

https://www.databridgemarketresearch.com/reports/global-3d-printing-gases-market

Comprehensive Overview of the 3D Printing Gases Market

Segments

- By Type: The 3D printing gases market can be segmented by type into nitrogen, argon, helium, and others. Nitrogen is widely used in the 3D printing process to create an inert atmosphere, preventing oxidation and ensuring high-quality prints. Argon is another commonly used gas, known for its ability to provide a stable printing environment. Helium is utilized for its low density and high thermal conductivity, making it suitable for specific printing applications.

- By Technology: The market can also be segmented by technology, including material extrusion, vat polymerization, powder bed fusion, material jetting, binder jetting, and others. Each technology requires specific gases to achieve optimal printing results. Material extrusion, for example, often utilizes nitrogen to improve print quality, while powder bed fusion methods may require argon for consistent printing conditions.

- By End-Use Industry: Another important segmentation of the 3D printing gases market is by end-use industry, which includes aerospace and defense, healthcare, automotive, electronics, and others. Each industry has unique requirements for 3D printing gases based on the materials being used and the desired output. For instance, the aerospace sector may require precise control over gas composition to meet stringent quality standards, while the healthcare industry may prioritize biocompatible gases for medical device manufacturing.

Market Players

- Linde plc: As one of the leading global suppliers of industrial gases, Linde plc plays a significant role in the 3D printing gases market. The company offers a range of gases tailored for additive manufacturing applications, ensuring high purity and quality for optimized printing processes.

- Air Liquide: Another key player in the 3D printing gases market, Air Liquide provides a variety of gases essential for additive manufacturing, including nitrogen, argon, and helium. The company's expertise in gas handling and distribution ensures reliable supply chains for 3D printing operations worldwide.

- Praxair Technology, Inc.: Praxair Technology, Inc., a subsidiary of Linde plc, is also a prominent player in the market, offering a comprehensive portfolio of 3D printing gases and equipment. The company's focus on innovation and sustainability drives the development of new gas solutions to meet the evolving needs of the additive manufacturing industry.

- Air Products and Chemicals, Inc.: With a strong presence in the industrial gas market, Air Products and Chemicals, Inc. supplies gases for various applications, including 3D printing. The company's commitment to research and development enables the creation of advanced gas technologies to enhance printing performance and efficiency.

- BASF SE: As a leading chemical company, BASF SE provides not only gases but also materials for 3D printing applications. The company's integrated approach to additive manufacturing includes gas solutions that complement its innovative range of 3D printing filaments and resins, offering customers a comprehensive additive manufacturing solution.

The 3D printing gases market continues to witness significant growth and evolution as advancements in additive manufacturing technologies drive demand for high-quality gases to enhance printing processes. One emerging trend in the market is the increasing adoption of specialized gases such as nitrogen, argon, and helium to cater to the specific requirements of different 3D printing technologies. Companies like Linde plc, Air Liquide, Praxair Technology, Inc., Air Products and Chemicals, Inc., and BASF SE are playing pivotal roles in providing tailored gas solutions to meet the diverse needs of the additive manufacturing industry.

In terms of segmentation by type, the use of nitrogen stands out as a crucial component in creating an inert atmosphere during the 3D printing process, ensuring the high quality and integrity of printed components by preventing oxidation. Argon is favored for its ability to maintain stable printing conditions, while helium's unique properties, such as low density and high thermal conductivity, make it suitable for specific printing applications that require precise control over the printing environment.

The segmentation of the market by technology also highlights the diverse gas requirements for different 3D printing processes. Material extrusion, a widely used technology, often utilizes nitrogen to improve print quality, while techniques like powder bed fusion may rely on argon to maintain consistent printing conditions. Understanding these technology-specific gas requirements is essential for market players to tailor their offerings and meet the growing demands of additive manufacturing applications across various industries.

Furthermore, the segmentation of the 3D printing gases market by end-use industry underscores the importance of catering to the unique needs of sectors such as aerospace and defense, healthcare, automotive, electronics, and others. Each industry has distinct requirements for gas composition and quality to achieve desired outcomes in 3D printing applications. For example, the aerospace sector demands precise gas control to meet stringent quality standards, underscoring the critical role of high-purity gases in ensuring the integrity of printed components.

Overall, the 3D printing gases market is poised for continued growth and innovation as market players focus on developing advanced gas solutions that enhance printing performance, quality, and efficiency. By understanding the specific gas requirements of different 3D printing technologies and end-use industries, companies can leverage opportunities for market expansion and differentiation in the evolving landscape of additive manufacturing.The 3D printing gases market is experiencing significant growth and evolution driven by advancements in additive manufacturing technologies. One key trend in the market is the increasing adoption of specialized gases such as nitrogen, argon, and helium to meet the specific requirements of different 3D printing technologies. These gases play a crucial role in ensuring the quality and integrity of printed components by creating ideal printing conditions and preventing oxidation. Market players like Linde plc, Air Liquide, Praxair Technology, Inc., Air Products and Chemicals, Inc., and BASF SE are actively providing tailored gas solutions to meet the diverse needs of the additive manufacturing industry.

Segmentation by type reveals the distinct roles of nitrogen, argon, and helium in 3D printing. Nitrogen is essential for creating an inert atmosphere, argon maintains stable printing conditions, and helium is suitable for specific applications due to its unique properties. Understanding the specific gas requirements for each type of printing technology is crucial for market players to deliver optimized solutions and meet the growing demands of the industry.

Moreover, segmentation by end-use industry highlights the varying needs of sectors such as aerospace and defense, healthcare, automotive, and electronics. Each industry requires specific gas compositions and quality standards to achieve desired outcomes in 3D printing applications. For example, the aerospace sector prioritizes precise gas control to meet stringent quality standards, emphasizing the critical role of high-purity gases in ensuring the quality of printed components across industries.

In conclusion, the 3D printing gases market is poised for continuous growth and innovation as companies focus on developing advanced gas solutions to enhance printing performance, quality, and efficiency. By addressing the unique gas requirements of different printing technologies and end-use industries, market players can capitalize on opportunities for expansion and differentiation in the dynamic landscape of additive manufacturing. The emphasis on specialized gases and tailored solutions reflects the industry's commitment to driving advancements in additive manufacturing and meeting the evolving needs of diverse sectors.

Assess the business share occupied by the company

https://www.databridgemarketresearch.com/reports/global-3d-printing-gases-market/companies

Analyst-Focused Question Templates for 3D Printing Gases Market Evaluation

- What is the market size snapshot of the 3D Printing Gases Market?

- What will be the growth curve over the next decade?

- What consumer types are covered in segmentation?

- Who are the most recognized brands?

- What is the market reaction to recent innovations?

- What is the country-wise growth comparison?

- What regional factors drive differentiation?

- What is the highest-growth territory for the next five years?

- Where is the strongest buyer activity occurring?

- What geopolitical shifts could impact the 3D Printing Gases Market?

Browse More Reports:

North America Data Center Cooling Market

SEA Data Center Cooling Market

Europe Deep Partial-thickness Thermal Burns Treatment Market

Middle East and Africa Deep Partial-thickness Thermal Burns Treatment Market

North America Deep Partial-Thickness Thermal Burns Treatment Market

Asia-Pacific Deep Partial-Thickness Thermal Burns Treatment Market

North America Dental Implants and Prosthetics Market

Europe Drive Shaft Market

Asia-Pacific Drive Shaft Market

Middle East and Africa Drive Shaft Market

North America Drive Shaft Market

Europe Drug Safety Solutions and Pharmacovigilance Market

Middle East and Africa Drug Safety Solutions and Pharmacovigilance Market

North America Drug Safety Solutions And Pharmacovigilance Market

Middle East and Africa Electro Hydraulic Servo Valve Market

Middle East and Africa X-Ray Inspection Systems Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience, which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- [email protected]

- Books

- Software

- Courses

- Movies

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness