-

Fil d’actualités

- EXPLORER

-

Pages

-

Groupes

-

Blogs

-

Développeurs

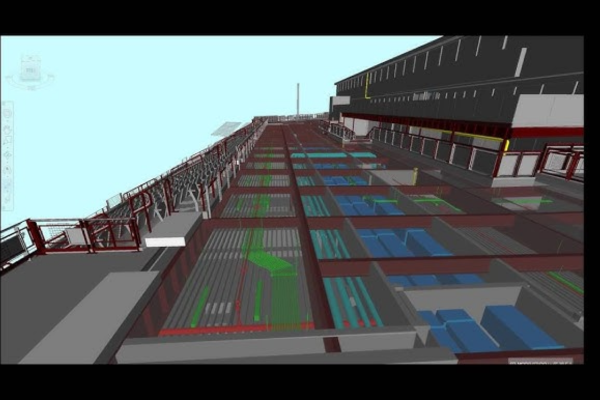

CAD-Integrated Estimation

In today’s hyper‑competitive construction and manufacturing markets in the U.S., speed, precision, and cost control matter more than ever. Clients demand tighter budgets, leaner schedules, and greater accountability. For estimators, that means the days of manually transcribing quantities from drawings into spreadsheets — with all the attendant risk of errors — are rapidly fading. Enter CAD‑Integrated Estimation, a streamlined approach that marries design and estimating in one continuous digital workflow. When properly implemented, it can reduce turnaround times, improve accuracy, and give firms a decisive edge in winning bids.

In this post, we’ll explore what CAD‑Integrated Estimation is, illustrate how it works (with U.S. use cases), outline the benefits and challenges, and show how Precision Estimator can help you adopt this capability successfully.

What Is CAD‑Integrated Estimation?

At its core, CAD‑Integrated Estimation (also sometimes called CAD-to-cost or design-estimate integration) refers to systems and workflows where the geometry, metadata, and features in CAD drawings feed directly into cost estimating calculations — with minimal manual re‑entry. Instead of extracting takeoff quantities manually from DWG, DXF, or BIM files, an integrated system can parse walls, slabs, beams, finishes, mechanical runs, or any defined components, and compute material, labor, and overhead automatically or semi‑automatically.

In more advanced implementations, this “pipeline” can incorporate rules, pricing databases, labor tables, and costing logic — enabling real-time adjustments as the design evolves. As described in contemporary engineering literature, the CAD‑to‑cost pipeline involves geometric parsing, feature extraction, normalization, and even machine learning or optimization to translate design data into accurate costs.

Some commercial products already combine CAD and estimating for building work: for example, BuildingWorks allows architects and builders to draft while simultaneously generating a full bill of quantities and cost summary. In industrial realms, platforms like ShouldCost DEEP integrate CAD/CAM geometry with cost modeling.

Why U.S. Firms Are Embracing It

1. Market Pressure & Scale

The U.S. remains a strong adopter of digital design and automation. The CAD software market in North America accounts for a significant share of global usage, and many U.S. firms already use 3D CAD, CAD/CAM, or BIM systems. As such, migrating to tighter integration between design and cost is a natural next step.

2. Profit Margins Under Squeeze

With rising material costs, supply chain volatility, and labor shortages, U.S. contractors and manufacturers face tight margins. Estimation mistakes can erode profitability. According to industry sources, companies that maintain high estimation accuracy outperform peers by margins exceeding 10–15%. Leveraging CAD‑integrated tools allows faster iterations and error reduction.

3. Speed Wins the Bid

In many U.S. markets, the first accurate, responsive bid often gets the job. When you can generate a cost estimate while design changes are still in flux, you can respond rapidly to clients’ adjustments — a competitive advantage.

Key Benefits of CAD‑Integrated Estimation

Let’s break down the main advantages:

A. Time Savings & Faster Turnaround

Because much of the heavy lifting is automated, you minimize manual takeoff and data entry. Estimators can focus on value-add tasks rather than replication. In some cases, firms report reducing estimate preparation time by 50% or more.

B. Fewer Errors & Better Consistency

Manual transcription errors, unit mismatches, or overlooked items often cause costly surprises later. With integration, matching geometry to cost rules ensures consistency. When the design changes, updates propagate automatically.

C. Real-Time “What‑If” Modeling

You can adjust material types, thicknesses, lengths, or finishes and immediately see the cost impact. This empowers design teams and owners to make trade-offs on the fly without resorting to offline spreadsheets.

D. Scalability & Repeatability

CAD‑based estimation scales better than custom spreadsheets. As your team and project volume grow, the integrated pipeline handles complexity more robustly.

E. Better Collaboration Across Design & Construction

When design and cost live in the same ecosystem, it fosters tighter coordination between architects, engineers, contractors, and estimators. Change tracking and version control become more transparent.

Common Use Cases and Examples

Building & Facilities Projects

A U.S. general contractor working on tenant fit-outs might use a CAD-integrated estimating tool to recalculate finishes, partition layouts, and MEP adjustments mid-design without re‑doing entire takeoffs. Tools like BuildingWorks allow drawing and instant cost feedback.

HVAC / Sheet Metal / Mechanical Trades

Systems like PractiCAM integrate CAD and estimating for HVAC and sheet metal trades, allowing estimators to trace duct routes or mechanical paths and link directly to labor tables and pricing.

Manufacturing & Fabrication

In parts manufacturing, platforms like ShouldCost DEEP interpret CAD features (holes, cutouts, pockets) and output cost estimates based on machining, labor, and material rules. In the U.S., advanced firms are adopting CAD-to-cost pipelines as part of their Industry 4.0 initiatives.

Construction AI Assistants

Emerging tools like Civils.ai accept CAD drawings or PDFs and automate takeoff and specification-based cost estimation using AI, reducing takeoff time by up to 90%.

Challenges & Best Practices for Implementation

While CAD-integrated estimation promises big gains, success hinges on careful planning and execution.

1. Data & Rules Governance

Your pricing databases, labor tables, overhead rates, and cost rules must be well maintained. Garbage in = garbage out. Ensure robust version control, auditing, and update protocols.

2. Clean, Consistent CAD Modeling

Better results come when CAD models follow standard naming, layering, and feature conventions. Encourage design users to adhere to modeling best practices so cost extraction is predictable.

3. Hybrid Human Oversight

In early adoption phases, maintain a human-in-the-loop review. Let the system do the heavy lift, but keep your estimator reviewing for anomalies or edge cases.

4. Training & Change Management

Staff must be trained not just on new tools but on the mindset of integrated workflows. Expect resistance at first; pilot with a few projects to build confidence.

5. Platform Compatibility & Interoperability

Choose estimation tools that support your CAD format (DWG, Revit, IFC, etc.). Interoperability is key — you don’t want costly file conversions to undermine value.

6. Incremental Deployment

Don’t rip and replace everything at once. Start with one trade (e.g. finishes or mechanical) or class of project. Refine your cost logic before scaling.

Why Precision Estimator Is Your Best Partner

At Precision Estimator, we specialize in helping U.S. firms adopt CAD‑Integrated Estimation without disrupting ongoing operations. Here’s how we deliver value:

· Tailored integration — We customize the CAD‑to-cost pipeline to your trades, estimating rules, and pricing structure.

· Data validation & cleanup — We scrub and harmonize your cost databases, labor tables, and CAD modeling standards so integration works predictably.

· Pilot projects — We help you roll out in phases, test reliability, and refine your workflow.

· Training & support — We provide hands-on training and mentoring to your estimators, design staff, and project teams.

· Continuous optimization — As your business evolves (new materials, labor shifts, market changes), we help update your logic and rules so you don’t lose edge.

By partnering with us, U.S. firms can accelerate time to value, reduce estimation risk, and boost their win rates — all while preserving project control and accuracy.

Conclusion:

CAD‑Integrated Estimation is no longer a niche luxury — it’s becoming a table-stakes capability for forward-thinking construction and manufacturing firms in the U.S. When design and cost truly talk to each other, you gain speed, precision, and agility to dominate competitive bids. But the integration journey demands discipline, domain expertise, and a measured rollout.

If your firm is ready to explore CAD-integrated estimating or you simply want to pilot a lean implementation in one trade, Precision Estimator is here to help. Let’s talk about your goals, evaluate your CAD environment and cost data, and chart a clear roadmap to greater estimating efficiency and profitability.

- Books

- Software

- Courses

- Film

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness